Recommended Products

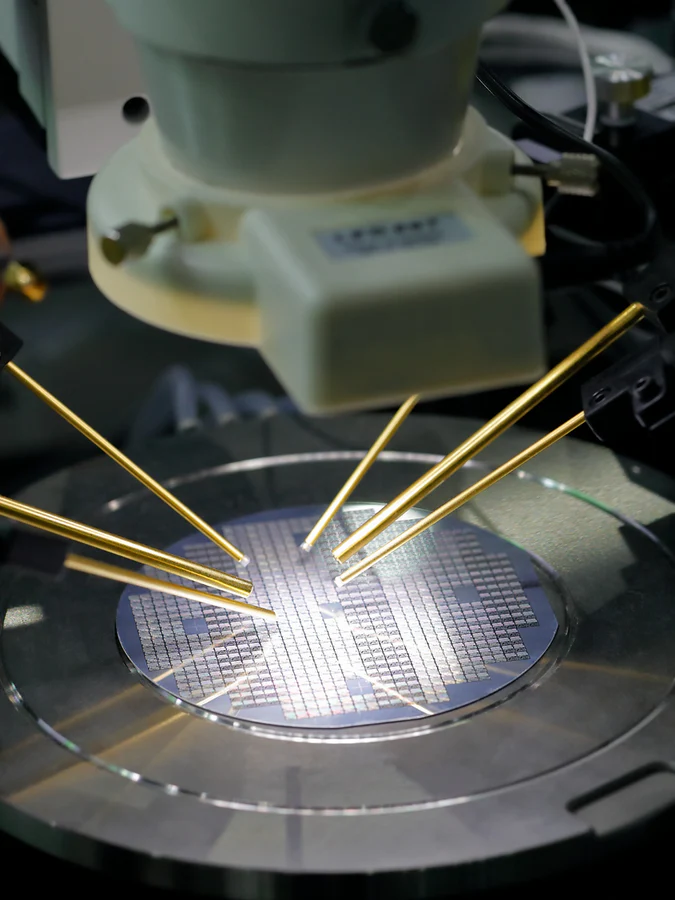

At Bridge Tronic Global, we leverage our extensive network and industry expertise to source high-quality semiconductor manufacturing equipment from trusted suppliers worldwide. Whether you're looking for cutting-edge technology or reliable pre-owned equipment, our sourcing capabilities ensure that you receive the best options tailored to your needs.

We understand that every client's requirements are unique, so we prioritize transparency, thorough vetting, and a deep understanding of the global market to secure the right equipment for your operations. Our team is dedicated to delivering timely, cost-effective solutions without compromising on quality or performance.

Refurbishment: Restoring Excellence, Maximizing Value

At Bridge Tronic Global, our refurbishment services breathe new life into used semiconductor manufacturing equipment, ensuring peak performance at a fraction of the cost. Our expert technicians meticulously restore equipment from leading brands like KLA and Hitachi, applying rigorous testing and quality control measures. Whether you need a single piece refurbished or a fleet of equipment overhauled, we deliver reliable, high-performing solutions that extend the lifespan of your assets while optimizing your budget.

English

English Chinese (Traditional)

Chinese (Traditional) French

French German

German Japanese

Japanese Korean

Korean