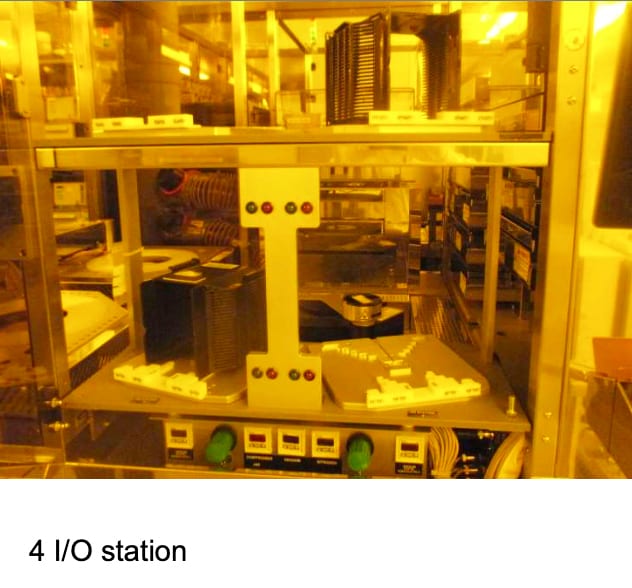

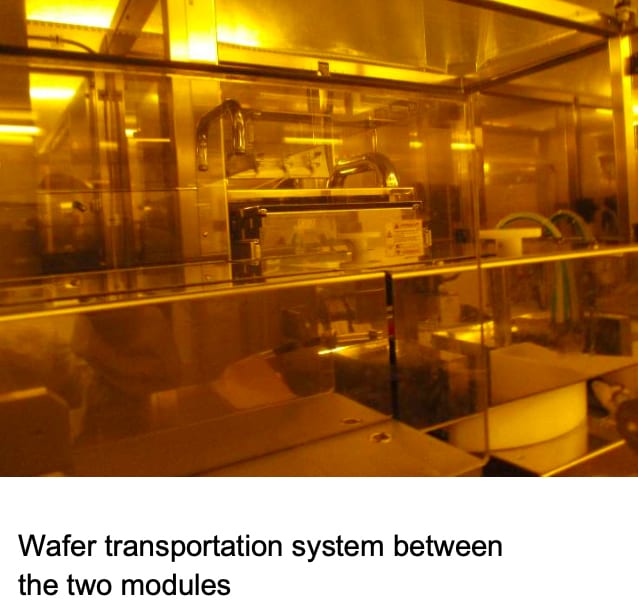

Karl Suss Twin Gamma 4 M Coater Developer

– 4 I/O stations, coater side, send/receive carrier for coating or developing

– 2 I/O stations developer side, deactivated and cannot be used

– I/O stations can optionally be equipped with 4 and 6 inch carriers

– Parallel operation is possible

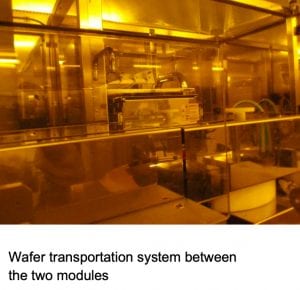

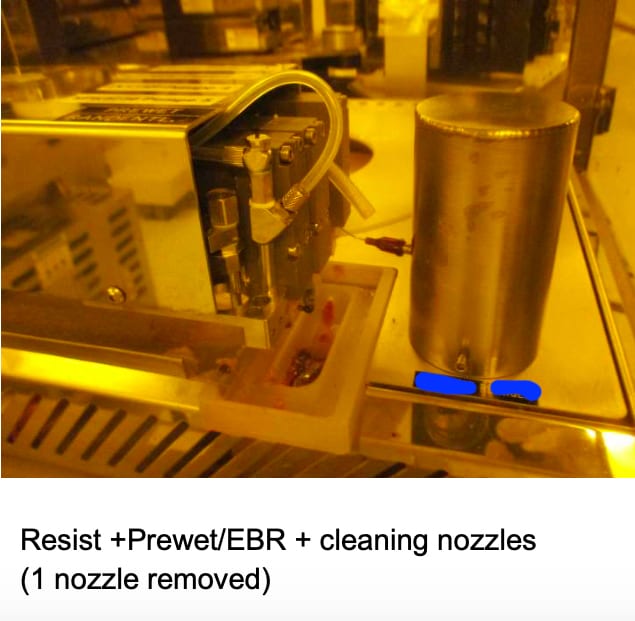

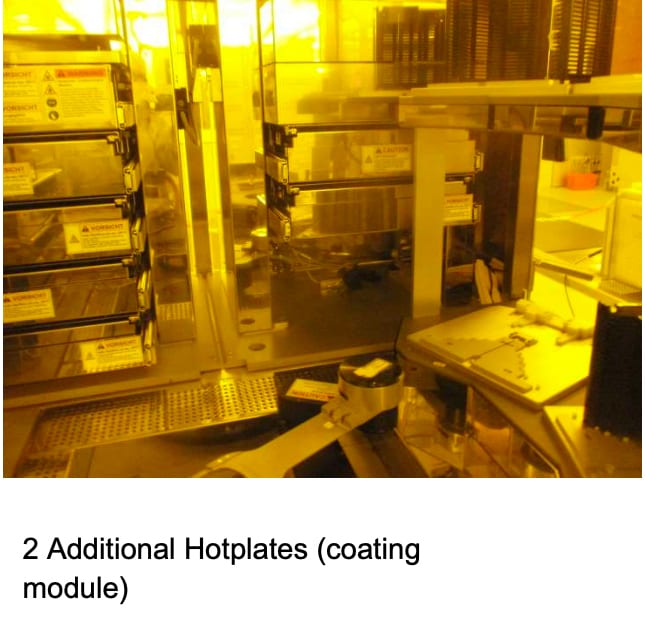

Coater Unit

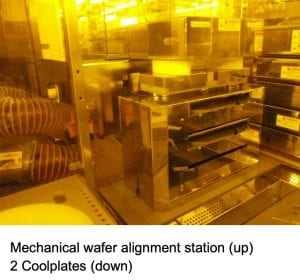

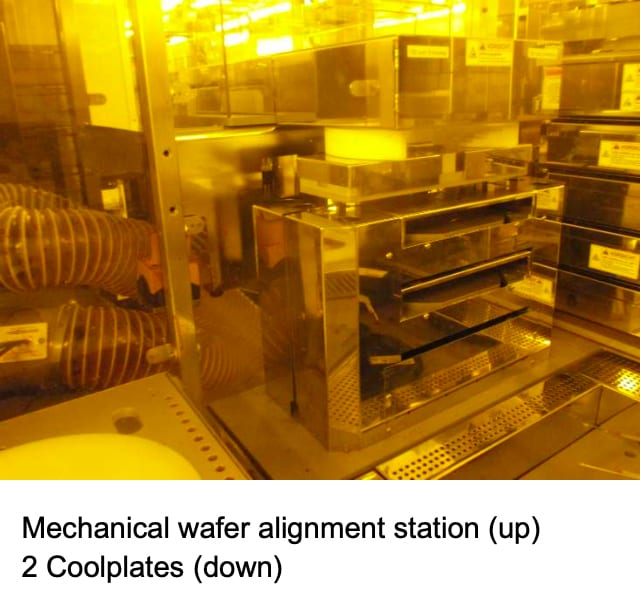

– 1 mechanical wafer alignment station (flat)

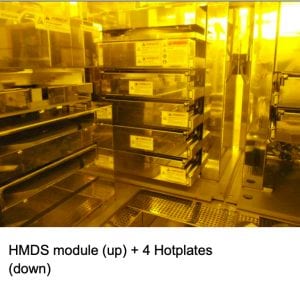

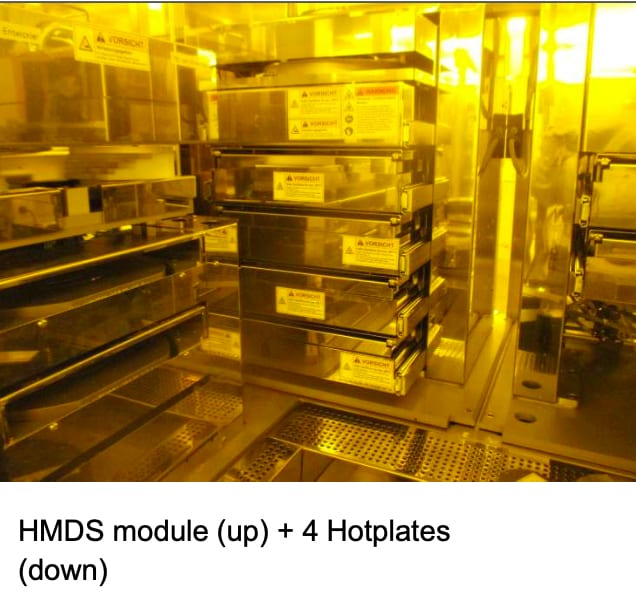

– 1 HMDS unit (bubbling system)

– 2 coater cups, spin speed 10 – 6000 rpm, acceleration 10 – 50000 rpm/s, open bowl

– 4 resist nozzles per coater cup

– Prewet /EBR nozzle

– (Solvent) nozzle for cleaning of resist nozzles

– Backside rinse

– 6 hotplates, contact, with vacuum, 60 – 250°C

– 2 coolplates, contact and with programable proximity 0.2 – 15 mm, step 0.1 mm, vacuum,

20 – 25°C

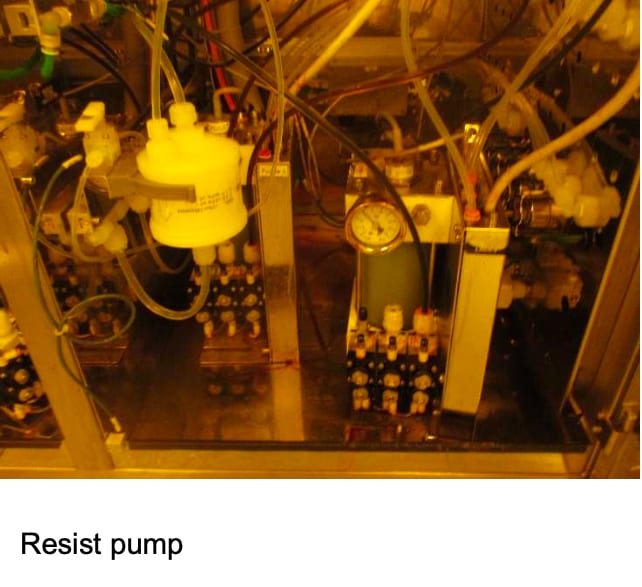

– 5 IDI pumps, low viscosity

– 3 resists, coater 1 + 2 1 resist, coater 1

– 1 resist, coater 2

– The machine is open to the top and no coater chamber / no temperature and humidity

control possible

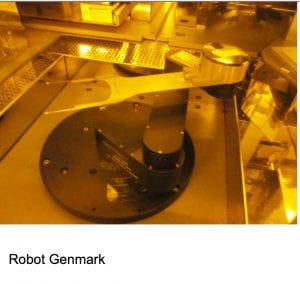

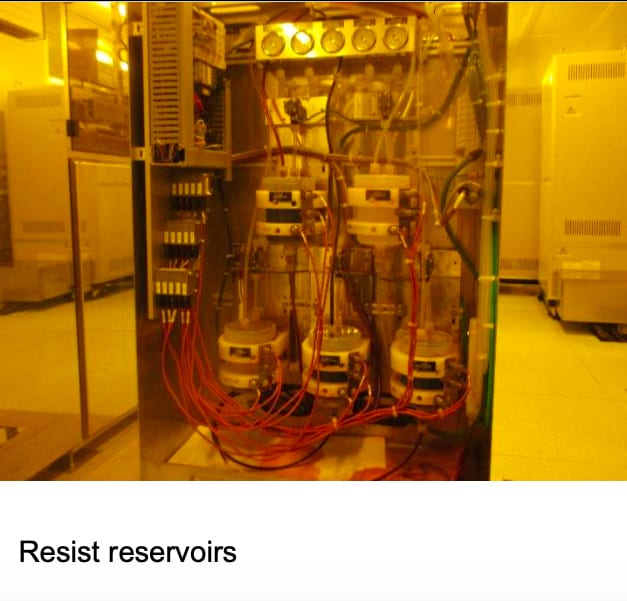

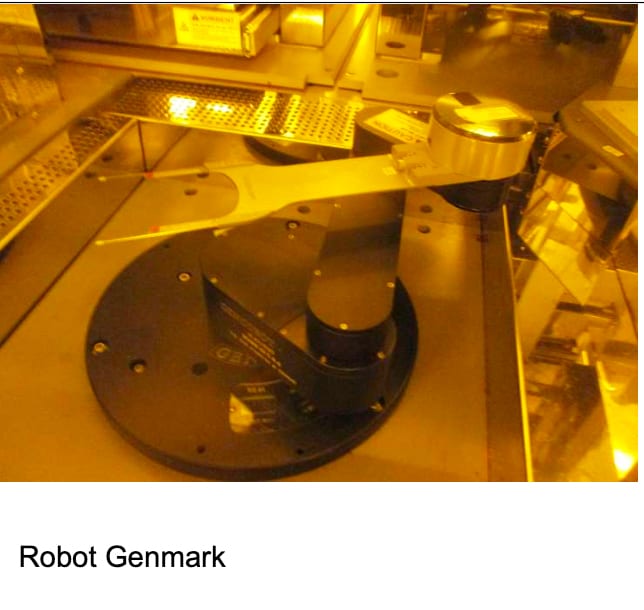

– Robot, Genmark GB4S with needle gripper Resist cabinet

– 5 resist bottles

– 5 resist reservoirs (~500 ml)

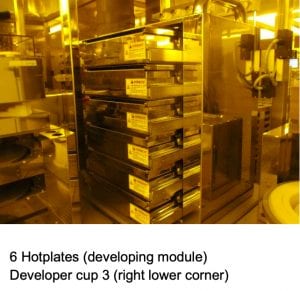

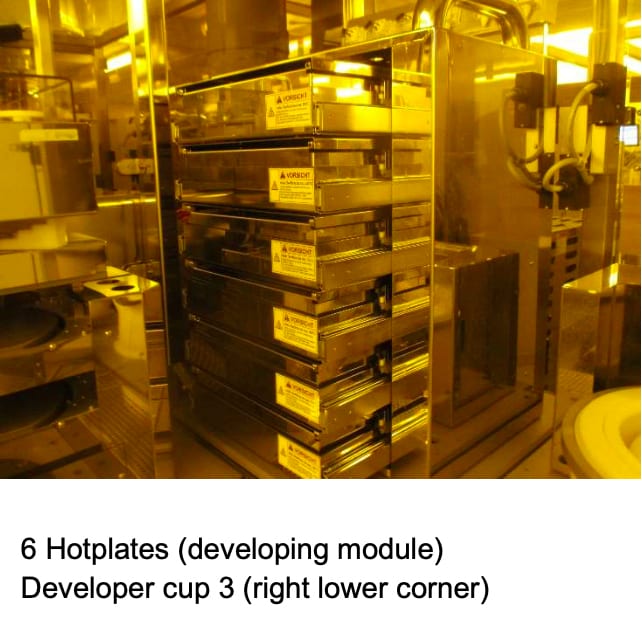

Developer Unit

– 1 mechanical wafer alignment station (flat)

– 3 developer cups, spin speed 10 – 6000 rpm, acceleration 10 – 50000 rpm/s

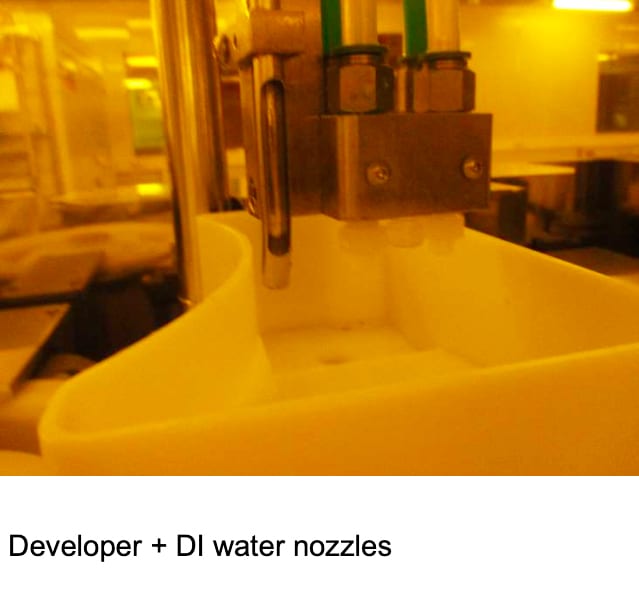

– 1 (puddle) developer nozzle per developer cup

– 1 DI water nozzle per developer cup

– Backside rinse

– 6 hotplates, contact, with vacuum, 60 – 250°C

– 2 coolplates, contact and with programable proximity 0.2 – 15 mm, step 0.1 mm,

vacuum, 20 – 25°C

– Robot, Genmark GB4S with needle gripper

Temperature control devices cabinet

– 6 thermostats, Fa. Julabo Compact Refrigerated circulator F30-C 1 per coater cup and all

Resists

1 per developer cup for developer

1 for all developer cups for DI Water

– 2 thermostats, Fa. Julabo Recirculation Coolers FC600 S 1 for all coolplates

1 for flange cooling (coater + developer)

Chemical cabinet

– 2 solvent tanks, stainless steel, 10 l, change tank system

– 2 developer tanks for developer cup 1+2, polyethylene (PE), 5 l, changing tank

system

– 2 developer tanks for developer cup 3, polyethylene (PE), 5 l, changing tank

system

Used chemicals

– HMDS

– Positive i-line resists

– Solvent

– TMAH based developer with surfactant, metal free

Send BTG Message:

InquireAd Details

-

Added: October 9, 2020

-

Views: 355