Product Details

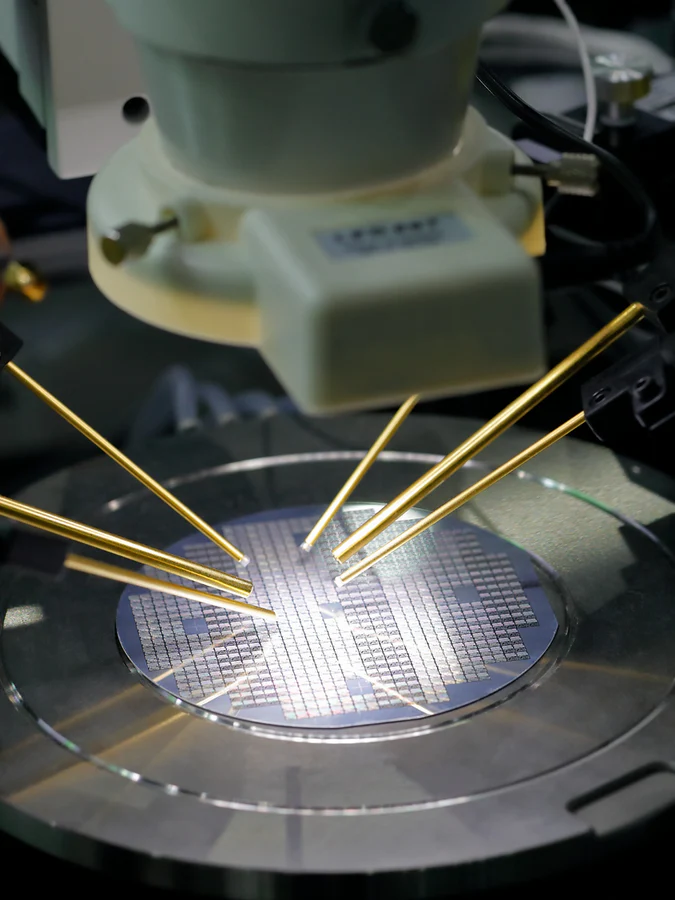

ASML Twinscan XT 1250 D ArF Scanner

English

English Chinese (Traditional)

Chinese (Traditional) French

French German

German Japanese

Japanese Korean

Korean